- Beijing jinyehong metallical zida za mac

- bjmmec@yeah.net

- + 18201347740 / + 86 13121182715

TC yopukutira zopanga za TC ya makina achitsulo oyenda

Kuyambitsa Zoyambitsa

Chotsani mphete zopondaponda (zomwe zimadziwikanso kuti Trusten Carbide Rogung) ali ndi katundu wabwino wa mafuta. Poyerekeza ndi zinthu zina, zimakhala bwino mogwirizana ndi kukana kutentha, kuvala motsutsana ndi mphamvu. Zochuluka, kuuma kwake kumachepetsa pang'ono pansi pa mikhalidwe ya kutentha kwambiri. Chifukwa chake, mphete zokulungira za Carbidide zimapangidwa ndi app yothamanga kwambiri ya waya. Ndipo kukula kwake, kumagwiritsidwa ntchito kwambiri popanga waya wa waya kwambiri, bar ndi bar yopumira.

Monga momwe zinthu zazogulitsa zathu, pali magawo awiri a WC-CO ndi WC-CO-CR omwe ali ndi zida zabwino kwambiri. Mphamvu zowerama komanso zovuta zolimbitsa thupi 2200 MPA ndi (4-) X106J / mongona komanso mphamvu zolimba komanso mphamvu zimadalira kuti wothandizira womangawo (a Co-NI-R). Pakadali pano, mphero yotsiriza nthawi zambiri imakhala yopangidwa ndi 8- 10. Chifukwa cha kukula kwakukulu kwa mawonekedwe okhwima, kolala yomwe ili kutsogolo kwa mipata ingalimbana ndi ntchito yayikulu. Chifukwa chake, kuvala kosavuta komanso kutopa kozama kwambiri ndikosanthula kwambiri, komwe kumatha kutopa kwambiri. mphete. Pakadali pano, mphero yomaliza imapangidwa ndi 8- 10 imayimanso. Chifukwa chake, kuvuta kwambiri ndi kutopa kwabwino kwambiri ndi zinthu zofunika kwambiri, komwe kumatha kutopa. Tidzalipira kwambiri ku kuvala kochepa komanso kutopa kofananira ndi mphete zokulungira.

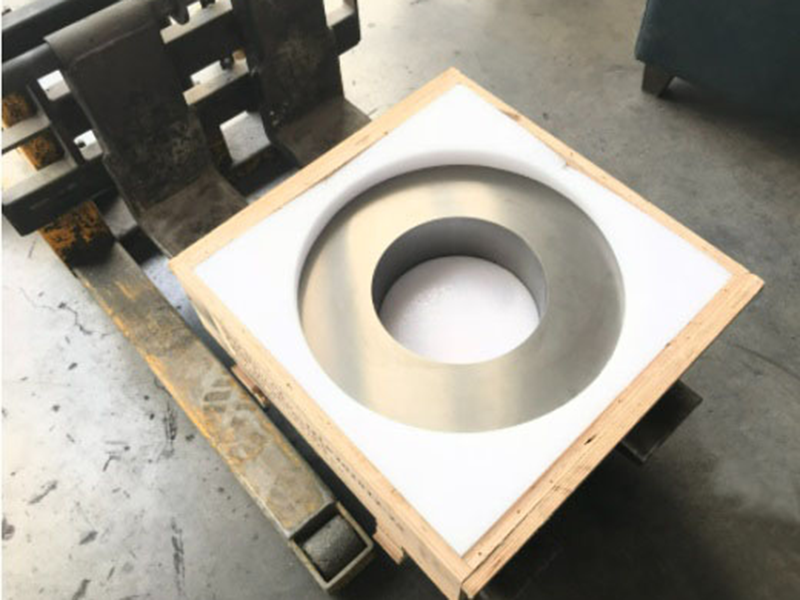

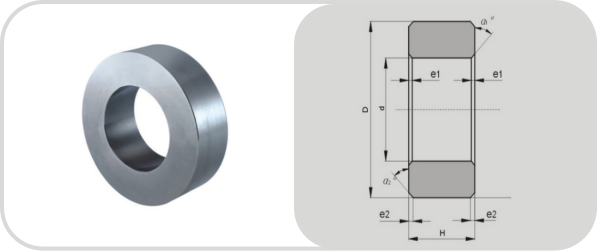

Kufotokozera za mphete ya TC

| Rang of ode (mm) | Mbitsani ng (mm) | Kutalika kwa kutalika (mm) |

| 145-40 | 87-280 | 300 |

Tungsten Carbider

Mitundu ya m'mimba yakunja: 154-50mm

Mitundu yapakatikatikati: 87-280mm

Kutalika kwa kutalika: 62-150mm

Gome la kutanthauzira ma roll

| Kulekerera kovomerezeka kwa ode, id, ndi kutalika kwa mphete (mm) | ||||

| Mtundu | Od≤200 mm | Od> 200mmm | ||

| Gumula | Kalasi yabwinobwino | Gumula | Kalasi yabwinobwino | |

| Kulekerera mad | ± 0,020 | ± 0,050 | ± 0,030 | ± 0,050 |

| Kulekerera kwa ID | +0.020 | +0.035 | +0.025 | +050 |

| Kulolera H | ± 0,025 | ± 0.100 | ± 0,050 | ± 0.100 |

| Gawo lalikulu la TC Mench Custical Staical Steict ndi kachulukidwe kwambiri | ||||

| Giledi | Kuchulukitsa (g / cm³) | Kuuma (HRA) | Trs (MPA) | Kugwiritsa Ntchito Kulimbikitsidwa |

| YG4C | 15 | 89.5 | 1800 | Amagwiritsidwa ntchito makamaka ngati mabatani ang'onoang'ono a mabatani a Percury komanso monga momwe mabatani oyembekezera amaperekera zofewa, zapakatikati. |

| YG6 | 15.8 | 89.5 | 1700 | Makamaka ngati mabatani ang'onoang'ono komanso okhazikika komanso ngati mabatani omwe akuyembekeza kuti adulidwe ofewa, apakatikati. |

| YG8 | 14.7 | 88.5 | 2300 | Makamaka ngati mabatani ang'onoang'ono komanso okhazikika komanso ngati mabatani omwe akuyembekeza kuti adulidwe ofewa, apakatikati. |

| Yg13c | 14.3 | 86 | 2500 | Amagwiritsidwa ntchito makamaka ngati mabatani ndi mabatani a Tricone Bits Rotetary-Persosive Brits ndi mabatani oyendetsa rock kuti aduleni pakati komanso movutikira. |

| Yg15 | 14 | 86.5 | 2500 | Ndizolimba, ndipo zimagwiritsidwa ntchito ngati mabatani ndi mabatani a zingwe zovunda, mabatani oyendetsa rock kuti achepetse mapangidwe olimba komanso ovuta .v |

Kulongedza & kutumiza